A successful roof flashing installation doesn’t start when you’re up on the ladder; it starts on the ground. Getting every tool, material, and safety check sorted out beforehand is what separates a professional, leak-proof job from a weekend of headaches and mid-job scrambles.

Your Pre-Installation Safety and Tools Checklist

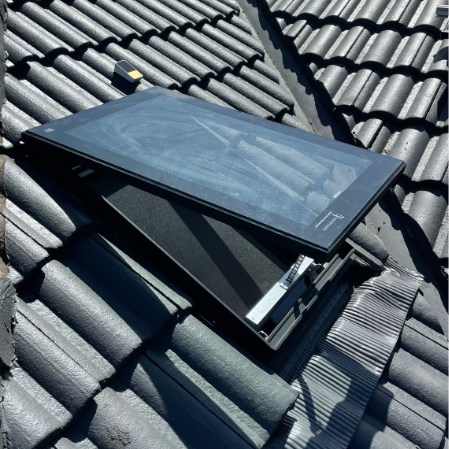

Before you even think about installing a skylight, you need to get your groundwork right. This isn’t just about grabbing your tools; it’s about setting up a safe, efficient workspace. For homes with characteristic tiled roofs, like many in the Balwyn area, this prep work is absolutely non-negotiable.

When you’re properly prepared, you can focus entirely on the quality of your work once you’re on the roof, instead of fumbling for a forgotten tool or having second thoughts about your safety setup. It’s this professional approach that guarantees a durable, weatherproof finish that won’t cause issues down the track.

Safety First: A Non-Negotiable Protocol

Working at height is risky business, but those risks are completely manageable if you’re strict about your safety protocol. Never, ever cut corners here. This is the absolute foundation of your entire project.

First up, check the weather. You want a clear, dry day with as little wind as possible. A damp tiled roof is like an ice rink, and a sudden gust of wind can turn a large piece of flashing into a dangerous kite.

Next, get your personal protective equipment (PPE) sorted.

- Safety Harness: This is not optional. If you’re on a pitched roof, you need a properly fitted safety harness secured to a solid anchor point. End of story.

- Grippy Footwear: Sturdy, soft-soled boots with excellent grip are a must to avoid slipping on roof tiles.

- Gloves and Safety Glasses: Protect your hands from sharp metal edges and your eyes from flying debris when you’re cutting or fastening.

Finally, make sure your ladder is on stable, level ground and extends at least one metre above the roofline. This gives you a safe and sturdy way to get on and off the roof.

A classic mistake is rushing the setup. Taking an extra 30 minutes to double-check your harness, ladder placement, and tool layout can be the difference between a smooth project and a serious accident.

Gathering Your Essential Tools and Materials

Having everything you need within arm’s reach makes the job cleaner, faster, and far more precise. When you’re working on a tiled roof, you need specific tools to handle the tiles without cracking them. Vivid Skylights provides roof flashings specifically tailored to suit tiled roofs for our skylights, and using the right gear ensures they fit perfectly.

For an even safer and more efficient pre-installation check, especially for larger or more complex roofs, some pros now use specialized drone roofing inspection software. This lets you spot any pre-existing issues from the safety of the ground.

Here’s a quick-reference checklist of what you’ll need to get the job done right. Having all these items organised in a tool belt or a bucket on the roof saves countless trips up and down the ladder, making your workflow safer and more efficient.

Essential Tools and Materials for Tiled Roof Flashing

| Category | Item | Purpose |

|---|---|---|

| Safety Gear | Safety Harness, Grippy Boots, Gloves, Glasses | Personal protection for working at height |

| Tile Handling | Pry Bar or Slate Ripper | To gently lift roof tiles without cracking them |

| Cutting & Shaping | Angle Grinder with Diamond Blade | For making clean, precise cuts in terracotta or concrete tiles |

| Cutting & Shaping | Tin Snips (Left, Right, Straight) | For accurately cutting and shaping metal flashing components |

| Sealing | Caulking Gun & High-Quality Silicone | To create a durable, weatherproof seal |

| Fastening | Cordless Drill/Driver | For securing the flashing with the correct screws |

| Marking | Measuring Tape, Pencil, Chalk Line | For accurate marking of the opening and flashing placement |

With this kit on hand, you’re set up for a professional-quality installation that will stand the test of time.

How Roof Flashing Actually Works on a Tile Roof

When you look at a skylight, it’s easy to think of the flashing as just some metal trim. But it’s so much more than that. Proper roof flashing is a clever, multi-layered system designed with a single, crucial purpose: to guide water safely down and off your roof, never giving it a chance to sneak underneath. This is especially vital on a tiled roof, where the gaps and overlaps create natural pathways for water.

Think of it like layering a waterproof jacket over a jumper. The flashing is the tough outer shell, and the roof underlayment is your base layer. For it to work, each piece must overlap the one below it, creating an unbroken path for rainwater to follow gravity. This basic principle of layering is the secret behind every successful roof flashing installation.

The Anatomy of a Skylight Flashing Kit

A standard flashing kit for a tiled roof isn’t just one piece of metal; it’s a system of several distinct parts, each with a specific job. Vivid Skylights provides roof flashings specifically tailored to suit tiled roofs for our skylights, ensuring a perfect fit with both the skylight unit and the unique profile of Australian tiled roofs.

Here’s what you’re working with:

- The Apron or Base Flashing: This is your starting point. It’s the piece that goes at the bottom (the downslope side) of the skylight. It sits right on top of the roof tiles below your opening, acting as the main channel to direct water away.

- Step Flashing: These are individual L-shaped pieces you’ll install along the sides. You weave them in with each course of tiles, making sure every piece overlaps the one below it. This “stepping” creates a waterproof staircase that moves water down and onto the apron flashing.

- The Head Flashing or Sill: This is the last and most critical piece. It gets installed at the very top (the upslope side) of the skylight. It slides under the course of tiles above your opening and sits over the side step flashings, completing the waterproof seal.

Getting this sequence right is non-negotiable. If you install these parts out of order, you break the chain of overlapping layers and create a direct entry point for water.

The core concept is simple: water should never be able to run under any piece of flashing. Each component must guide water over the next one in the sequence, all the way down the roof.

Integrating with Roof Tiles and Underlayment

The real magic happens when the flashing system works in tandem with both your tiles and the roof underlayment (often called sarking). Before any flashing goes on, the underlayment around the roof opening should be carefully cut and folded up the sides of the skylight frame. This creates a secondary, internal water barrier—your last line of defence.

Then, the metal flashing is installed over this, and the tiles are put back in place around it. While the base flashing sits on top of the tiles, the side and head flashings are partially covered by them. This mechanical integration means that even heavy, wind-driven rain hitting the sides of your Balwyn home gets caught by the step flashing and channelled away harmlessly. You can see how our custom-designed systems achieve this by checking out our tile roof flashing kits.

When you understand why each piece goes where it does, the installation process stops being a simple checklist and becomes a logical puzzle. It’s this knowledge that ensures your skylight will be a source of beautiful light, not a source of frustrating leaks, for decades.

A Practical Guide to Installing Skylight Flashing

Alright, you’ve got the theory down. Now it’s time to get on the roof and put that knowledge into practice. This is where we walk through the hands-on process of installing your Vivid Skylights flashing system on a classic Aussie tiled roof. The secret to turning a hole in your roof into a stunning, leak-proof feature is all about being meticulous and following the right sequence.

The whole job is methodical. You start by prepping the opening just so, and then layer each flashing piece correctly to build a watertight barrier. We’re going to focus on the specific techniques that separate a DIY job from a professional, long-lasting installation that’ll stand up to years of weather.

This diagram breaks down the core sequence: getting the base aligned, sealing up the joints, and adding the final trim.

If there’s one thing to take away from this, it’s that sequence is king. Each step builds on the last to create a single, unified system that sheds water exactly as it should.

Preparing the Roof Opening and Tiles

Your first job on the roof is to get the area around the skylight’s frame ready. This means carefully removing—and sometimes cutting—tiles to make sure the flashing can sit perfectly flat and integrate with the roof.

Grab a pry bar or a slate ripper and gently lift the tiles immediately surrounding the opening. You’ll need to pull off enough of them to give yourself a clear workspace around the entire skylight curb. Just make sure you stack them somewhere safe and out of the way.

Next, you’ll probably need to cut some of the tiles that will sit right up against the skylight’s sides. A rookie mistake is trying to snap them or using the wrong tool, which leaves you with ugly, jagged edges that ruin the final look.

- Mark Your Cuts: Put a tile back in its spot and mark a clean, straight line where it needs trimming to fit snugly against the frame.

- Use the Right Tool: An angle grinder with a diamond blade is your best friend here. It gives you a sharp, clean cut on both concrete and terracotta tiles, preventing any nasty chipping or cracks.

- Allow for a Small Gap: Leave a little breathing room, about 5-10mm, between the cut edge of the tile and the skylight frame. This gap allows for thermal expansion and stops the tile from putting pressure on the flashing.

Don’t rush this part. A poorly prepared opening will fight you every step of the way, making it a nightmare to install the flashing and creating potential leak points down the track.

Installing the Flashing Components in Sequence

With the opening prepped, it’s time to install the flashing system. Remember, the sequence is everything. Always work from the bottom up, making sure every new piece overlaps the one below it. This is the golden rule of any roof flashing installation guide.

The Base Flashing (Apron)

This is the very first piece to go on. The base flashing, often called an apron, sits at the bottom edge (the downslope side) of the skylight. It’s designed to be placed over the row of tiles directly below the opening. Its whole job is to catch water shedding off the skylight glass and the rest of the flashing, directing it safely down onto the roof.

Secure it to the skylight curb for now, but don’t fasten it down to the roof tiles just yet. This piece is the foundation of your water-shedding system.

Step Flashing Along the Sides

Next up is the step flashing, which you’ll install up both sides of the skylight. These are individual, L-shaped pieces of metal that you weave into the courses of tiles as you go.

Here’s how it works for each piece:

- Place the first piece of step flashing at a bottom corner, making sure it overlaps the base flashing.

- Lay the first roof tile for that row over the top of it.

- Place the next piece of step flashing over that tile, ensuring it overlaps the previous piece of flashing.

- Lay the next tile in the course.

You just repeat this “metal, tile, metal, tile” pattern all the way up both sides of the skylight. This layering creates a robust, staircase-like defence that channels water exactly where it needs to go.

Pro Tip: Don’t ever rely on sealant to fix gaps in your step flashing. If you’ve installed it correctly with proper overlaps, it will be completely waterproof on its own. Sealant is for specific joints, not for covering up sloppy work.

The Head Flashing (Sill)

The final and most crucial piece is the head flashing. This goes at the top edge (the upslope side) of the skylight, and its mission is to stop water from getting in behind the top of the unit.

This piece absolutely must be installed under the course of tiles above the skylight and over the top pieces of your side step flashing. This completes the overlapping chain, ensuring any water running down the roof from above is directed cleanly over the skylight and onto the step flashing on either side.

Finishing Touches for a Watertight Seal

With the main components in place, a few professional finishing touches will guarantee a durable, bomb-proof seal. For anyone wanting a broader look at the whole project, from cutting the hole to the final interior trim, you can check out our guide on how to install a skylight.

A key technique used by seasoned roofers is creating “dog ear” folds at the corners where the base and head flashing meet the sides. This involves making a small diagonal cut and folding the corner back on itself. It creates a tiny, raised dam that stops wind-driven rain from being forced sideways into the joint.

When it comes to sealant, less is definitely more. Its purpose is to seal small, specific gaps and fastener heads, not to act as a primary water barrier. Overusing sealant looks messy and can actually trap water.

Proper flashing installation is fundamental in the Australian roofing industry. Building standards like SA HB39 specify that flashing overlaps must be a minimum of 75mm to effectively block water. It’s no surprise that flashing failures are a leading cause of expensive water damage in homes.

Finally, put all the tiles you removed back into place, making sure they sit neatly over and around your new flashing. Vivid Skylights provides roof flashings specifically tailored to suit tiled roofs for our skylights, like those common in suburbs such as Balwyn, so the fit should be snug and clean. You’ll be left with a skylight that is as reliable as it is beautiful.

Securing Flashing to Withstand Australian Weather

Getting your flashing installed is one thing, but making sure it stays put is another beast entirely. We all know how unforgiving Australian weather can be. From the gusty winds that batter our coastlines to the intense downpours that can swamp a roof in minutes, your flashing fasteners are under constant assault. An improperly secured flashing system is almost always the first point of failure, turning a small oversight into a major, costly leak.

This part of our roof flashing installation guide is all about the specific fastening techniques you need to stand up to these powerful forces. It’s not just about pinning the metal down. It’s about creating a fixing that resists wind uplift, stops annoying rattling, and holds its ground for decades. Following these standards is what separates a professional, leak-free skylight installation from a future problem, even when the wildest storms roll through.

Why Screws Beat Rivets for a Superior Hold

When it comes to securing your flashing, you have a couple of choices for fasteners. But for sheer durability and holding strength, screws are the hands-down winner over rivets. While rivets are fine for holding two pieces of metal together on a workbench, they offer next to no resistance against pull-out forces. During a high-wind event, the negative pressure on your roof acts like a giant vacuum, literally trying to suck the flashing clean off.

Screws, on the other hand, have threaded shafts that bite firmly into the timber roof battens or the skylight frame itself. This provides far superior holding power that stops uplift in its tracks. This is especially critical for homes in areas like Balwyn, where the combination of tile roofs and established trees can create unpredictable and powerful wind tunnels. Using the right fasteners is a small detail, but it makes a world of difference to the long-term resilience of your roof.

Think of it this way: the fasteners are the anchors holding your entire flashing system to your house. Skimping here is like using cheap rope to moor a boat—it might look fine on a calm day, but it’s guaranteed to fail when you need it most.

Nailing the Right Fastener Spacing and Overlaps

Where you place your fasteners is just as crucial as the type you use. If you space them too far apart, you’ll get “wind chatter,” where the flashing vibrates and flaps in the breeze. That constant movement might seem harmless, but over time it causes metal fatigue, leading to cracks and failure right at the fixing points.

To stop this from happening, a standard spacing interval is essential. Industry best practice is to place fasteners at approximately 500mm intervals. This is tight enough to hold the flashing snugly against the roof structure, preventing any movement or noise. It also ensures the wind load is distributed evenly across the entire length of the flashing, so no single point takes all the stress.

Just as important is the overlap between your flashing sections. In a pierce-fixed system—where the fasteners go directly through the metal—a minimum overlap of 150mm is non-negotiable. This ensures that even if wind drives rain horizontally across your roof, the water can’t get underneath the join. In fact, guidelines from major Aussie roofing manufacturers show that flashings at roof edges are subjected to negative wind loads that can almost double the stress forces. This makes robust fastening and generous overlaps an absolute necessity for a continuously waterproof seal.

The easiest way to get this right is to start with a high-quality, purpose-built skylight flashing kit. These kits are designed from the ground up to meet these exact standards for Australian tiled roofs, taking the guesswork out of the equation.

Choosing Flashing Materials That Last

Picking the right flashing material isn’t just some final detail; it’s one of the most critical calls you’ll make for the long-term health of your roof. The Aussie sun, particularly in suburbs like Balwyn, is absolutely relentless on building materials. A cheap, flimsy flashing might look the part on day one, but it won’t take long for it to get brittle and crack under the constant barrage of UV rays and wild temperature swings.

When that happens, you’re looking at a failure that’s not only expensive but incredibly frustrating to deal with down the track. This is why you need to go for flashing engineered specifically for our harsh climate. You’re after a product that stays flexible and maintains a watertight seal for years, sidestepping the common failures of generic, off-the-shelf stuff.

The Problem With Substandard Materials

A lot of the generic flashing you find simply isn’t cut out for the job. These materials often miss the key ingredient: UV stabilisers. Without them, the Aussie sun just breaks down their chemical structure, causing them to shrink, go rigid, and pull away from sealants and fasteners.

The moment that happens, you’ve basically opened a door for water to get into your roof space. Even a tiny, hairline crack in a piece of flashing can set off a chain reaction, leading to major water damage inside your home over time. It’s a classic case of a small problem turning into a huge, expensive one. That’s why investing in a quality, purpose-built system from the get-go is the smartest long-term move you can make.

The most expensive roofing job is the one you have to do twice. Choosing a material designed for Australian conditions from the outset eliminates the single biggest cause of premature flashing failure and significantly reduces your future maintenance headaches.

For instance, Vivid Skylights provides roof flashings specifically tailored to suit tiled roofs for our skylights. This guarantees a perfect fit and a material that can take whatever the local climate throws at it, keeping your home protected for years to come.

Comparing High-Performance Flashing Options

When you’re weighing up materials for your roof flashing installation guide, two things should be front of mind: UV resistance and flexibility. The best modern flashing products are designed to nail both.

Here’s a quick rundown of some solid choices:

- Lead-Free Flashing: A fantastic modern alternative to old-school lead, these are usually made from composite materials. They’re light, non-toxic, and incredibly flexible, which makes them a dream to mould around the tricky shapes of roof tiles.

- Aluminium Flashing: This is a durable, corrosion-resistant option, often powder-coated for an extra layer of defence. That coating gives it excellent UV protection, making it a great pick for any visible flashing.

- Polyisobutylene (PIB) Based Flashing: This is the high-tech end of the spectrum. These are advanced, self-bonding materials that are amazingly flexible and built to last. They create a totally waterproof seal that expands and contracts with your roof’s natural movement.

Australia’s brutal climate demands roofing materials engineered for extreme UV exposure. Choosing a UV-resistant flashing can slash your maintenance needs by around 30-50% because it stops common issues like cracking and shrinkage before they start. It’s a choice that can add years to your roof’s functional lifespan.

Of course, a good roof does more than just keep the rain out; it protects your investment. Getting a handle on how quality materials and a professional installation add to your home’s long-term worth is key. For more on improving your property’s market appeal, you can find great strategies on how to raise property value. After all, a solid, leak-free roof is a huge selling point.

Got a Question About Your Flashing?

Even with the best guide in hand, it’s natural to have a few questions pop up, especially when you’re about to get up on the roof. Confidence comes from knowing what to expect, so let’s tackle some of the most common queries we hear.

Plenty of homeowners, especially those with tiled roofs common in suburbs like Balwyn, run into the same hurdles. Getting these cleared up beforehand can make all the difference.

Can I Just Reuse My Old Flashing?

I get asked this all the time, and it’s a tempting shortcut, but the answer has to be a firm no. Your old flashing was custom-bent, nailed down, and sealed into place for its specific job. Trying to pry it off without bending, tearing, or creasing it is next to impossible.

Even if you could, it’s spent years battling the Aussie sun and rain. That exposure leads to metal fatigue and microscopic cracks you can’t even see. It’s just not worth the risk. Starting fresh with a new flashing kit is the only way to get that guaranteed, leak-proof seal and keep your warranty intact.

What Do I Do If I Crack a Tile During the Job?

It happens to the best of us. You’re moving around, you put a bit too much pressure in the wrong spot, and crack. The absolute worst thing you can do is pretend it didn’t happen or try to bog it up with silicone. A cracked tile is an open invitation for water to get under your brand-new flashing, completely defeating the purpose of your hard work.

The rule is simple: if a tile cracks, it gets replaced. No exceptions. This is why you should always have a few spare matching tiles ready before you even climb the ladder. It turns a potential disaster into a five-minute fix.

What’s the Right Sealant to Use for Flashing?

This is not the place to cut corners. You need a high-quality, neutral-cure silicone sealant that’s specifically made for roofing and outdoor use. These formulas are designed to stay flexible through scorching summers and chilly winters, maintaining a strong bond to metal and tiles.

Stay away from cheap, all-purpose acrylic caulks. They’ll go brittle and fail within a year or two, and you’ll be back on the roof chasing leaks. A great flashing job uses sealant sparingly, but where it is used, it has to be the best available.

Your Flashing Installation Questions Answered

Still have a few things on your mind? We’ve put together this quick-fire table to answer some other common questions, especially for those in areas like Balwyn tackling a classic tiled roof project.

| Question | Answer |

|---|---|

| Do I need to flash over or under the sarking (underlayment)? | Your sarking is the last line of defence. You should cut it and fold it up the sides of the skylight frame first. The flashing then gets installed over the sarking to direct water away. |

| How tight should I fasten the screws? | You’re aiming for “snug,” not “crushed.” The screws should be tight enough to create a solid seal against the gasket, but not so tight that you buckle or warp the metal flashing itself. |

| What if my roof pitch is very low? | Standard flashing kits are designed for standard pitches. For low-slope roofs, water drains much slower and needs extra protection. Vivid Skylights provides roof flashings specifically tailored to suit tiled roofs for our skylights, including solutions for low-pitch roofs to handle this. |

| Can I install flashing in any weather? | Definitely not. Pick a calm, dry day. A wet tiled roof is incredibly slippery and dangerous, and a sudden gust of wind can turn a big piece of flashing into an uncontrollable sail. |

Thinking through these points before you start will help your installation go off without a hitch. A bit of preparation is all it takes to ensure a professional, leak-free result that will light up your home for years.

Ready to bring beautiful, natural light into your home with a perfectly sealed skylight? Vivid Skylights provides premium flashing kits specifically designed for Australian tiled roofs, ensuring a perfect, leak-free fit every time. Explore our range and get a quote at https://vividskylights.com.au.