You can think of roof flashing as the silent guardian of your home. It’s a thin, tough, weather-resistant material installed at the most vulnerable spots on your roof—the joints, corners, and anywhere something pokes through. Essentially, it’s your roof’s first and most important line of defence against water sneaking into your house, especially around tricky areas like chimneys, vents, and skylights.

Understanding Roof Flashing and Its Critical Role

Picture a submarine. Its hull is incredibly strong, but the real test is how well it’s sealed around the hatches and periscopes. Roof flashing does the exact same job for your home. It’s the high-performance seal that protects the weakest points from water getting in.

Without it, even the most expensive roofing materials are compromised, leaving your home open to leaks, timber rot, and serious structural damage. That’s why getting your head around the different roof flashing types is a must for any Australian homeowner.

Any time you cut a hole in a roof—whether it’s for a plumbing vent, a chimney, or a beautiful new skylight—you’ve just created a potential leak waiting to happen. Flashing brilliantly solves this problem by creating a layered, waterproof barrier that cleverly channels rainwater away from these openings and safely down into your gutters.

The Guardian of Your Investment

If you’re thinking about adding natural light with a skylight, the flashing is the secret sauce to a successful, stress-free installation. This is especially true for the high-quality, double-glazed skylights from Vivid Skylights, a leading supplier of double glazed fixed and operable skylights in Australia. We know a skylight is only as good as its seal against the weather.

That’s why we don’t just recommend proper flashing; it’s the core component that allows us to stand behind our 10-year leak-free warranty. It’s what ensures your investment in a brighter home—whether it’s one of our fixed models, or our versatile electric and solar powered operable skylights—is protected for years to come. For those wanting to dig deeper, there are plenty of comprehensive roofing resources out there.

Flashing is not just an accessory; it is an essential, integrated part of any roofing system. Its correct installation determines whether a roof penetration, like a skylight, will be a source of natural light or a chronic source of leaks.

An Australian Evolution in Materials

The materials used for roof flashing here in Australia have come a long way, driven by environmental standards and our unique climate challenges. Decades ago, lead was the go-to choice, but its use was banned on roofs used for rainwater collection, forcing the industry to innovate.

Today, we use advanced materials that combine the strength of aluminium with modern polymers to create flashing solutions that are far superior and safer.

At Vivid Skylights, we supply custom-designed flashing kits with every single skylight. This ensures a perfect fit for Australian roofs, and because we can deliver our skylights nationwide in Australia, you get a premium solution no matter where you are. You can learn more about protecting your home in our complete guide to roof leak prevention.

Exploring Key Roof Flashing Types and Their Jobs

Think of it this way: a well-tailored suit is only as good as its seams. The same goes for your roof. It relies on a specialised system of roof flashing types to protect every joint, corner, and penetration. They all work together as a team, each with a specific job, to create a completely waterproof barrier.

Getting your head around these different roles is the key to understanding the clever defence system that keeps your home dry.

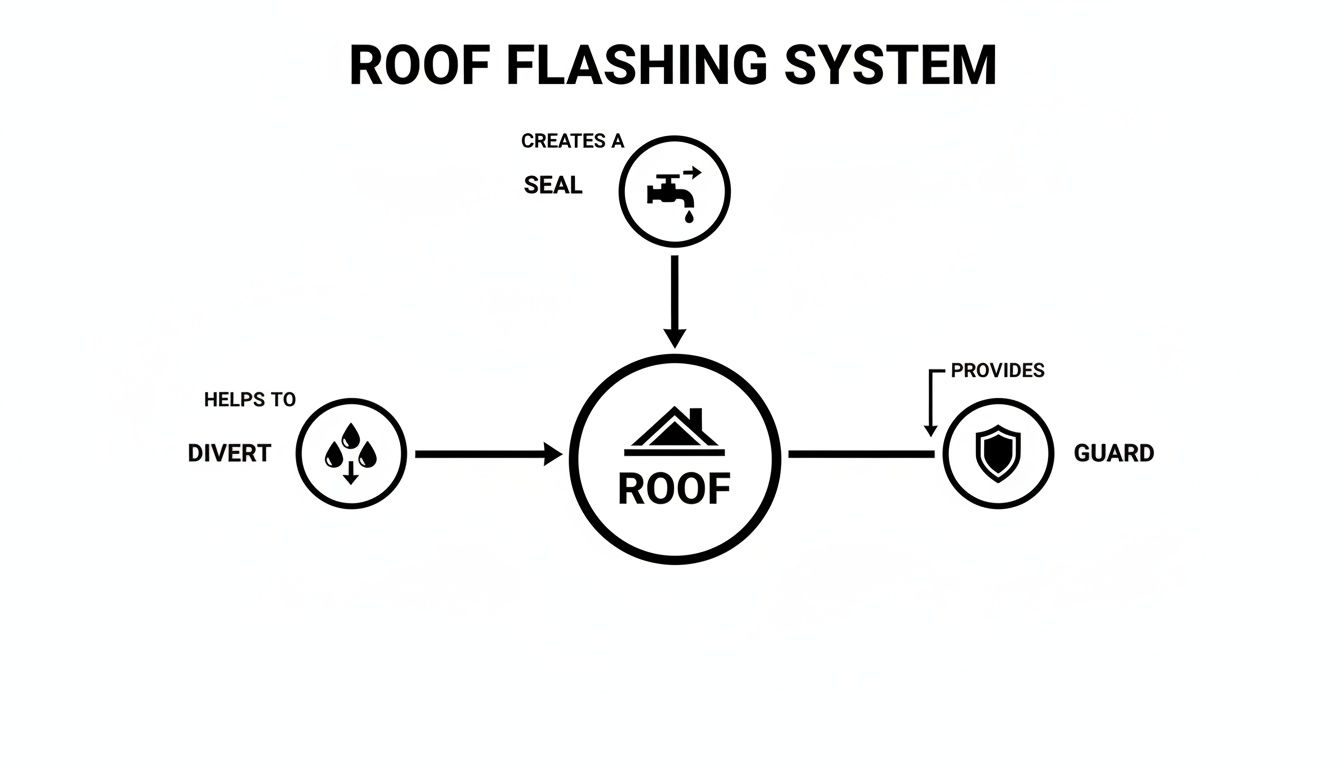

This diagram breaks down how the different functions of flashing—sealing, guarding, and diverting—come together to manage water across your entire roof.

As you can see, flashing isn’t just a single piece of metal. It’s a complete system designed to tackle water from every angle.

Step Flashing: The Overlapping Armour

Picture the overlapping scales on a suit of armour. That’s the exact principle behind step flashing. You’ll find it where a sloped roof meets a vertical wall, like the side of a chimney or where a second storey juts out.

Instead of one long, continuous piece, step flashing uses individual sections woven into each layer of shingles or tiles. Each piece overlaps the one below it, forming a “step” pattern that forces water down the roof, stopping it from sneaking in behind the wall. This layered design is brilliant because it allows the building materials to naturally expand and contract without breaking the seal.

Valley Flashing: The Central Rain Gutter

Roof valleys are those V-shaped channels where two sloping roof planes meet. During a heavy downpour, these intersections act like a major waterway, funnelling a huge amount of runoff. This makes them one of the most common spots for leaks if they aren’t flashed properly.

Valley flashing is a large, W-shaped metal channel that gets installed before the roof covering goes on. That central crimp in the ‘W’ is its secret weapon—it stops water rushing down one side from pushing its way up under the tiles on the other side. It’s the high-capacity drainage system for your roof’s busiest intersections.

Apron Flashing: The Protective Shield

Think of apron flashing (sometimes called continuous flashing) as a protective bib or shield. It’s a single, long piece of flashing that sits where the bottom of a chimney, dormer, or skylight meets a downward-sloping roof.

Its job is simple but absolutely vital: it blocks water from getting into the seam at the base of the structure. Instead, it directs the flow harmlessly over the top of the tiles or shingles below. For any skylight, the apron flashing is the critical first line of defence at its lowest point.

Pipe Flashing: The Snug Rubber Boot

Your roof probably has several pipes poking through for plumbing vents or fans, and each one is a potential leak waiting to happen. Pipe flashing, often called a ‘boot’ or ‘pipe jack’, is the purpose-built solution.

It’s made of a flat base that slips under the surrounding roof material and a flexible, cone-shaped sleeve that wraps tightly around the pipe. A rubberised gasket at the top creates a watertight collar that can move with the pipe as it heats and cools. It’s a beautifully simple and effective way to seal these very common roof penetrations.

A complete flashing system is greater than the sum of its parts. Each type of flashing is designed for a specific junction, and only when they are all installed correctly can they provide total, leak-free protection for complex structures like skylights.

Kickout Flashing: The Small But Mighty Diverter

Don’t underestimate kickout flashing. This small but incredibly important piece, also known as a diverter, is installed where a roof edge stops against a vertical wall—for example, where your garage roof meets the side of the house.

Its one and only job is to “kick” water away from the wall and shoot it directly into the gutter. Without it, water would pour down the side of your wall, causing staining, rot, and serious moisture damage over time. It’s a perfect example of how a tiny, well-placed component can save you from thousands of dollars in future repairs.

Skylight Flashing: The Complete Custom System

A skylight isn’t just a simple hole in the roof; it’s a major penetration that demands a combination of flashing types all working together perfectly. This is where a custom-designed flashing kit becomes absolutely non-negotiable. As a leading supplier of double glazed fixed and operable skylights, we at Vivid Skylights know that a generic, one-size-fits-all approach just doesn’t cut it.

Our engineered flashing kits, included with every single skylight, contain all the necessary, pre-formed components:

Sill Flashing: An apron piece for the bottom edge.

Side Flashing: Step flashing pieces for the sides.

Head Flashing: A top piece to guide water safely around the unit.

This integrated system is precisely designed to create a completely sealed barrier, whether you have a classic tiled roof or corrugated iron. If you want to dive deeper into how flashing works with specific profiles, you can learn more about our dedicated flashings for corrugated roofs.

Whether you opt for an elegant fixed skylight or one of our smart electric or solar powered operable skylights, the custom kit ensures a perfect, leak-free fit. And because we can deliver our skylights nationwide in Australia, you get a complete, engineered solution designed for Australian conditions, brought right to your door.

Choosing the Best Flashing Materials for Australian Conditions

Picking the right material for your flashing is a bit like choosing the right tyres for your car—what works perfectly in one environment might fail spectacularly in another. Under the harsh Aussie sun and unpredictable downpours, the material you choose has a massive impact on how long your roof will stay leak-free.

It’s easy to just look at the price tag, but a smart choice involves thinking about durability, resistance to corrosion, and whether it will play nice with your existing roof.

Common Materials on Australian Roofs

Let’s break down the most popular options you’ll find protecting homes across the country, from coastal suburbs to the rural outback. Each one has its own set of pros and cons.

Colorbond Steel: A true Australian icon. At its core, Colorbond is a Zincalume steel base with a tough, baked-on paint finish. It offers fantastic corrosion resistance and comes in a huge range of colours to match your roof, making it a go-to for both looks and performance.

Zincalume: Think of this as the unpainted version of Colorbond. It has a zinc/aluminium alloy coating that’s highly durable and cost-effective, but its raw, metallic look isn’t for everyone.

Aluminium: Lightweight, totally rust-proof, and easy to shape, aluminium is a brilliant all-rounder. It’s especially good in coastal areas where salt spray can eat away at other metals. This flexibility is why it’s a top pick for complex shapes, like those needed for skylight flashing kits.

Copper: This is the premium choice. Copper is incredibly long-lasting and develops that beautiful green patina over time. The catch? Its high cost means you’ll usually only see it on heritage restorations or high-end architectural projects.

Lead-Free Composites (e.g., Wakaflex): Modern alternatives like Wakaflex give you the flexibility of old-school lead flashing without the environmental and health headaches. These materials are self-bonding and can be stretched to fit tricky roof profiles, making them a favourite for repairs and complex jobs.

To make the choice a little easier, here’s a quick comparison of the most common materials you’ll encounter.

Comparison of Common Roof Flashing Materials

This table compares the key features of popular roof flashing materials to help you choose the best option for your Australian home.

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Colorbond Steel | Excellent durability, wide colour range, great corrosion resistance. | Can be scratched during installation, more expensive than Zincalume. | Modern homes where matching roof colour and long-term performance are key. |

| Zincalume | Highly durable, cost-effective, excellent corrosion resistance. | Industrial look, can’t be used with certain other metals (e.g., copper). | Sheds, industrial buildings, or projects where budget is a priority over aesthetics. |

| Aluminium | Lightweight, rust-proof, very malleable for complex shapes. | Can be prone to denting, not as strong as steel. | Coastal properties, skylight flashing, and roofs with intricate designs. |

| Copper | Extremely long-lasting (100+ years), beautiful aesthetic patina. | Very expensive, requires specialised installation. | Heritage buildings, architectural features, and premium custom homes. |

| Lead-Free Composites | Highly flexible, safe to handle, self-bonding, great for repairs. | May not have the same longevity as metal, higher initial cost than some metals. | Complex roof junctions, chimney flashing, and retrofitting around pipes. |

This table should give you a solid starting point, but there’s one more crucial factor to consider before making a final decision.

The Critical Issue of Galvanic Corrosion

You can’t just mix and match flashing metals with your roof and gutters. It’s absolutely critical to understand galvanic corrosion—an electrochemical reaction that happens when two different metals touch in the presence of moisture.

Think of it as a tiny battery where one metal sacrifices itself to protect the other, causing it to rapidly corrode and fail.

A classic example is installing a copper flashing on a Zincalume roof. The copper will accelerate the corrosion of the steel, dramatically shortening the lifespan of your roof. Always ensure your flashing material is compatible with your roof, gutters, and fasteners.

This is why you have to look at the whole system. With 58% of Australian roofs made from Colorbond or other metals and 33% featuring tiles, compatibility isn’t just a recommendation—it’s essential for a long-lasting, leak-proof roof.

Why Vivid Skylights Chooses Powder-Coated Aluminium

At Vivid Skylights, we’ve thought long and hard about these challenges. As a leading supplier of double glazed fixed and operable skylights, we need a flashing solution that is tough, versatile, and looks great on any Aussie home.

That’s why our custom flashing kits are engineered from high-grade, powder-coated aluminium. For a deeper dive into how this all comes together, check out our guide on metal window flashing.

This choice gives our customers several key advantages:

Superior Durability: Aluminium is naturally immune to rust, which means it lasts, even in salty coastal air.

Aesthetic Match: The black powder-coating provides a sleek, modern finish that blends in perfectly with the most popular Australian roof colours, whether you have tiles or metal.

Guaranteed Compatibility: It’s a stable material that won’t cause galvanic corrosion when installed with common roofing materials like Colorbond or tiles.

So, whether you’re installing a fixed skylight for maximum light or an electric or solar powered operable skylight for fresh air, our flashing system is designed to create a perfect, watertight seal. And because we deliver our skylights nationwide in Australia, you get a complete, engineered solution built to handle local conditions, no matter where you live.

The Unbeatable Advantage of Custom Skylight Flashing Kits

While generic roof flashing types like step or apron flashing work for standard roof junctions, a skylight is a completely different beast. When you install one, you’re not just covering a join; you’re creating a large, deliberate opening in your roof’s waterproof membrane. This calls for a specialised, purpose-built defence against water.

It’s here that a one-size-fits-all approach just doesn’t cut it. A custom flashing kit becomes the only real solution.

Think of it like getting a suit tailored versus buying one off the rack. The off-the-rack suit might look okay from a distance, but it’ll never sit quite right across the shoulders or at the waist. In the same way, generic flashing can’t account for the exact dimensions and unique profile of a specific skylight model, leaving tiny gaps and weaknesses that water will always find.

Engineered for a Perfect Seal

A custom skylight flashing kit is an integrated system. Every single component is engineered to work in perfect harmony with the next. At Vivid Skylights, a leading supplier of premium skylights, we live and breathe this principle. That’s why a complete, custom-designed flashing kit is included with every single skylight we sell. Our kits aren’t an afterthought or an optional extra; they are a core, non-negotiable part of the product itself.

These kits are precision-made to integrate flawlessly with our double glazed fixed and operable skylights. They’re specifically designed for the common roof profiles found right across Australia, whether you have classic tiles or modern metal sheeting.

Using the manufacturer-provided flashing kit isn’t just a recommendation—it’s mandatory. It’s the only way to guarantee a watertight seal, achieve peak performance, and protect your 10-year leak-free warranty.

This system creates a multi-layered barrier against the elements. The individual flashing components work together as a team, expertly guiding water safely around the skylight and down your roof. You can dive deeper into the specifics of our engineered systems in our detailed guide on skylight flashing kits.

The Anatomy of a Skylight Flashing Kit

A high-quality skylight flashing kit contains several key pieces, each with a critical job to do. When they’re assembled correctly, they form an impenetrable fortress around your skylight.

Sill Flashing (Apron): This piece sits at the bottom, or downslope, edge of the skylight. It’s the first line of defence, acting as the primary shield that directs the bulk of the water flow over the top of the roof tiles or sheeting below.

Side Flashing (Steps): These are individual, overlapping L-shaped pieces that run up the sides of the skylight. They are carefully woven into the roofing material, creating a stepped channel that stops water from creeping in from the sides.

Head Flashing: Positioned right at the top of the skylight, this component catches water from the roof area above and diverts it around the sides of the unit. This clever design prevents water from pooling and eventually finding a way in.

Together, these pre-formed parts eliminate all the guesswork. There’s no need for risky on-site fabrication, ensuring a professional and reliable installation every single time.

Adapting to Modern Roofing Demands

The need for precision flashing has only grown as Australian homes have evolved, especially with the rise of solar technology. The adoption of solar roof flashing in Australia has surged right alongside the explosive growth in residential solar panel installations. In fact, as of October 2024, more than one-third (36%) of Australian households now use a photovoltaic (PV) system to generate their own electricity.

This trend creates a parallel demand for specialised flashing that can integrate seamlessly with these systems. Discover more insights about this trend on aztecau.com.au.

This is particularly relevant for our solar powered operable skylights, which need flawless flashing for both waterproofing and to protect their electrical integrity. Whether you choose a sleek fixed model, a convenient electric skylight, or an energy-efficient solar one, our custom kits provide the exact fit required.

Plus, with our ability to deliver our skylights nationwide in Australia, you can be confident you’re getting a complete, engineered solution designed for a leak-free future.

How to Spot Common Flashing Failures Early

Catching a flashing problem before it turns into a major, destructive leak can save you thousands of dollars. Think of it as being your roof’s first line of defence. With a bit of practical knowledge, you can spot the telltale signs of failure from the safety of the ground, long before you see a dreaded water stain on your ceiling.

Learning what to look for will help you know exactly when it’s time to call in a professional for a proper inspection. It’s a simple skill that can ultimately extend the life of your entire roof system.

Visual Checks You Can Do from the Ground

You don’t need to get up on a ladder to spot the most obvious red flags. In most cases, a pair of binoculars and a keen eye are all you need to give your roof’s most vulnerable points a quick health check.

Here are the clear signs of trouble to look for:

Visible Rust and Corrosion: Orange or reddish-brown streaks are a dead giveaway. If you see them running down from chimneys, vents, or skylights, it means the metal flashing is breaking down and can no longer repel water effectively.

Cracked or Peeling Sealant: The sealant or caulking used around flashing joints takes a beating from the harsh Australian sun. Over time, it becomes brittle and cracks, leaving tiny gaps that are an open invitation for water to seep in.

Loose or Bent Sections: Flashing should sit snug and flat. If you spot sections that are lifted, bent, or pulling away from the roof surface, they’ve already failed. This is often caused by strong winds or shoddy installation.

Understanding these failure points is the first step. For a deeper dive into more severe scenarios, check out this guide on what you need to know about Roof Flashing Problems.

Subtle Warning Signs Inside Your Home

Sometimes, the earliest clues of flashing failure don’t show up on the roof at all—they appear inside your house. These subtle signs often point to a slow leak that’s been quietly developing over time.

Catching an interior sign of a leak early is crucial. By the time you see a stain on your ceiling, moisture has already penetrated your roof deck, insulation, and plasterboard, making the repair far more complex and costly.

Keep an eye out for these interior indicators:

Water Stains on Ceilings or Walls: These discoloured patches, often yellowish or brown, are the classic sign of a leak. Pay extra attention to areas directly below skylights, chimneys, or where walls meet the ceiling.

Peeling Paint Near the Ceiling: Moisture getting into your plasterboard will eventually cause the paint to bubble, peel, or flake away. It’s a sure sign that something is wrong above.

A Musty Odour in the Attic: If your roof space has a persistent damp or musty smell, that’s a strong signal of trapped moisture, very often caused by a leaking flashing joint.

If you spot any of these issues, especially around a skylight, it’s definitely time to get a professional assessment. You can find more on tackling these specific problems in our article on skylight leak repair. Getting ahead of the problem is the best way to protect your home and your investment.

Of course, here is the rewritten section, crafted to sound completely human-written and natural, following the style of your provided examples.

Get a Brighter Home, Guaranteed Leak-Free

You can spend a lot of time getting your head around all the different roof flashing types, but the smartest way to guarantee a leak-free home is to choose a product that was designed with a high-quality, fully integrated flashing system right from the start. That’s the core principle behind every skylight we offer at Vivid Skylights. We are a leading supplier who delivers an expertly engineered, complete solution built for total peace of mind.

Our industry-leading double glazed skylights offer exceptional thermal efficiency, which helps keep your home comfortable all year round. We have a range of models to suit every Australian home, from elegant fixed units to versatile electric and solar powered operable skylights that give you the ultimate convenience and ventilation.

The Vivid Skylights Difference

The real secret sauce is the custom flashing kit that’s included and delivered with every single skylight. We know a perfect seal isn’t just important—it’s everything. So, we’ve taken all the guesswork and risk out of the equation by getting rid of generic or on-site fabricated flashing.

Choosing Vivid Skylights isn’t just about adding beautiful, natural light to your home. It’s about investing in an engineered system where the skylight and its flashing are designed to work together perfectly, backed by a comprehensive warranty.

Our commitment to quality means you get a flawless fit and a guaranteed leak-free result, whether you have a tiled or metal roof. And because we can deliver our skylights nationwide in Australia, homeowners everywhere can get their hands on this superior solution. Your journey to a brighter, more beautiful, and worry-free home starts with a system designed from the ground up to last.

Common Questions About Roof Flashing

Even after getting to grips with the different roof flashing types, you might still have a few things you’re wondering about. Let’s tackle some of the most common questions we hear from homeowners, especially those thinking about a new skylight.

Can I Install New Flashing Myself, or Do I Need a Pro?

While a skilled DIYer might be tempted to handle a small flashing repair, installing a skylight and its purpose-built flashing system is a whole different ball game. It’s a technical job where even tiny mistakes can lead to major water damage down the track.

To guarantee a perfect, watertight seal and keep your product warranty fully intact, getting a professional installer is always the best way to go. A qualified roofer has the right tools, the know-how, and the experience to lock everything down for a secure, leak-free result that will protect your home for years.

How Long Should Roof Flashing Last in Australia?

The lifespan of your roof flashing really comes down to two things: the quality of the material and how well it was installed. High-grade materials like Colorbond steel or the powder-coated aluminium used in Vivid Skylights’ kits can easily last 20 to 30 years.

Keep in mind, though, that the flexible sealants used around the flashing might need an inspection every 5-10 years. They can start to break down under the harsh Australian sun. A regular roof check-up is the smartest way to make sure your flashing is still doing its vital job.

What Happens If I Use the Wrong Flashing for My Roof Type?

Using the incorrect flashing for your specific roof profile is one of the biggest culprits behind persistent roof leaks. It’s a simple mismatch; a flashing kit designed for a corrugated metal roof just won’t create a proper seal on a tiled roof, and the other way around.

This is a non-negotiable part of the installation. It’s precisely why every single one of our double glazed fixed and operable skylights comes with a custom-designed flashing kit for your specific roof type. Using the wrong one will void your warranty and almost certainly lead to water getting in.

Does Flashing Need Regular Maintenance?

Yes, absolutely. Your roof flashing should be a key checkpoint in any routine roof inspection. Maintenance is usually pretty straightforward and involves checking for any debris buildup—like leaves or twigs—that could trap moisture and hold it against the flashing.

It’s also smart to look over the sealants for any cracks or gaps and keep an eye out for any signs of corrosion or physical damage. A quick annual check by a professional can spot these small issues before they snowball into costly problems, giving you complete peace of mind.

Ready to bring beautiful, natural light into your home with a solution engineered for a leak-free future? Explore our range of fixed, electric, and solar-powered operable skylights at Vivid Skylights. All our products are delivered nationwide with a custom flashing kit and a 10-year warranty.