Think of a roof access hatch as more than just a simple door. It’s really the essential service gateway to your building’s most critical systems. It acts as the primary, secure entry point for maintaining everything that keeps your property functional and safe, from the HVAC units on the roof to plumbing vents and solar panels.

Think of a roof access hatch as more than just a simple door. It’s really the essential service gateway to your building’s most critical systems. It acts as the primary, secure entry point for maintaining everything that keeps your property functional and safe, from the HVAC units on the roof to plumbing vents and solar panels.

Why Safe Roof Access Is a Building Essential

Imagine your building’s roof as its mission control. This is where you’ll find the air conditioning units, communication gear, plumbing vents, and even solar arrays – all the heavy lifters that keep things running smoothly. Without a safe and designated entry point, getting to this equipment becomes a high-risk, inefficient, and potentially damaging chore. This is exactly why dedicated access hatches for roofs are non-negotiable.

A proper hatch transforms a hazardous climb into a structured, secure process. Instead of someone precariously balancing on a temporary ladder—a massive fall risk—a roof hatch integrated with a fixed ladder system provides a permanent, reliable pathway. This isn’t just about making things easier; it’s a fundamental part of modern building management and operational safety.

The Cornerstone of Efficiency and Safety

Good roof access is the very cornerstone of proactive maintenance. When technicians can get to equipment easily and safely, routine checks actually get done on schedule. This stops minor issues from snowballing into expensive, catastrophic failures.

A well-designed hatch also protects the building’s envelope. Every time someone uses a temporary, makeshift solution to get on the roof, there’s a real risk of damaging the roofing membrane, which is a fast track to water ingress. Our guide on effective roof leak prevention goes into more detail on just how crucial sealed penetrations are.

A properly specified roof hatch keeps essential building functions running smoothly by making maintenance predictable and safe. It’s an investment in operational continuity, asset protection, and, most importantly, worker safety.

Here in Australia, this focus on safety is baked into our regulations. Strict workplace safety rules heavily influence the market, pushing for standardised, compliant solutions. In fact, by 2023, over 65% of commercial buildings had installed hatches compliant with Australian Standards for fall prevention during rooftop work. This regulatory landscape is a constant reminder of why choosing the right access solution is so critical for any building owner.

Decoding the Different Types of Roof Hatches

Not all roof hatches are created equal. Choosing the right one is a lot like picking the correct tool for a job—you wouldn’t use a screwdriver to hammer a nail, and you definitely shouldn’t install a small personnel hatch when you need to move large equipment. Getting to know the main types is key to making sure you get the perfect fit for your building.

The most common model you’ll come across is the single-leaf hatch. Think of this as the standard entryway to your rooftop. It’s got a single hinged lid, usually square or rectangular, and is perfectly suited for one person to pop up onto the roof for routine inspections or maintenance. Most come with gas struts to help lift the lid, making it a smooth, one-person operation.

Personnel vs. Equipment Access

But what happens when the job involves more than just a person and a toolbox? That’s when a single-leaf model just won’t cut it.

This is where double-leaf hatches come into play. These are the heavy-duty workhorses of the roof access world, featuring two doors that open from the centre. Their much larger opening gives you all the clearance you need to safely move bulky items like HVAC units, ductwork, or other significant equipment onto or off the roof.

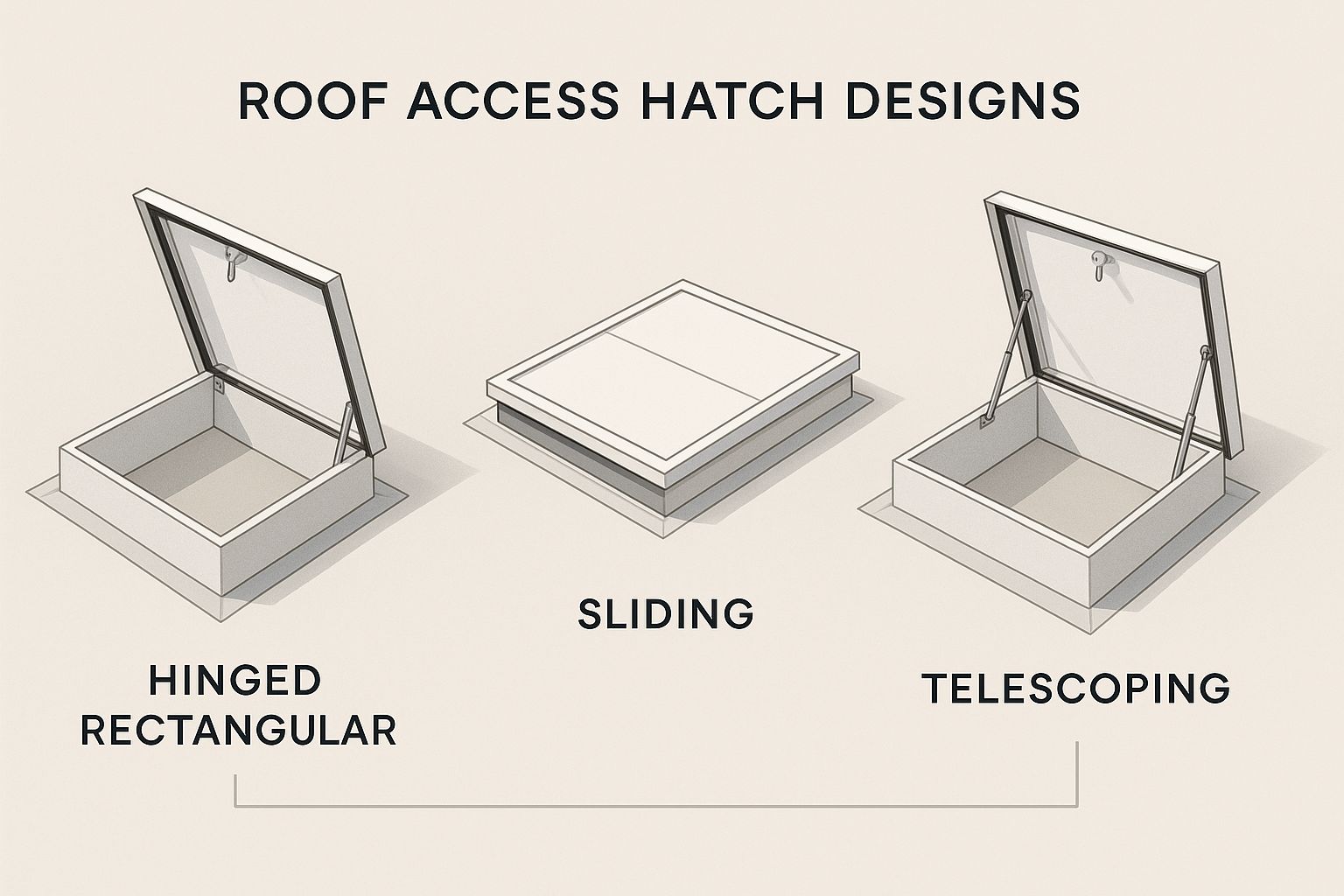

The diagram below shows just how different the designs can be, giving you a top-down look at how each one operates.

As you can see, each design—from a simple hinged lid to more complex sliding models—is engineered for a specific purpose, whether that’s simple entry or maximising the clear space available.

To make things a bit clearer, here’s a quick comparison of the most common types you’ll find on the market.

Roof Hatch Type Comparison

| Hatch Type | Primary Use | Common Size Range | Key Feature |

|---|---|---|---|

| Single-Leaf | Routine personnel access for maintenance and inspections. | 600x600mm to 900x900mm | Simple, single-lid design, often with gas strut assistance for easy opening. |

| Double-Leaf | Moving large equipment, machinery, or tools onto/off the roof. | 1200x1200mm to 1500x3000mm | Two doors opening from the centre, providing a large, unobstructed opening. |

| Smoke Vent | Emergency smoke and heat ventilation during a fire. | Varies by regulation | Automatic opening mechanism triggered by fire alarm systems. Life safety device. |

| Glazed/Polycarbonate | Providing both roof access and natural daylight to the space below. | Similar to single-leaf sizes | Features a transparent or translucent lid made of durable, impact-resistant material. |

This table should help you quickly pinpoint which hatch style aligns with what you’re trying to achieve on your project.

Specialised Hatch Solutions

Beyond standard access, some situations call for hatches that do more than just open and close. These specialised options are designed for unique building requirements, often blending access with other important features like safety, lighting, or even aesthetics.

- Smoke Vents: These are life-saving devices first and access points second. They’re designed to pop open automatically during a fire to let toxic smoke and heat escape, which helps with evacuation and gives firefighters better access. They are not meant for regular day-to-day use.

- Glazed or Polycarbonate Hatches: Perfect for spaces that need both roof access and a bit of natural light. These models have a transparent or translucent panel, letting daylight filter into the building while still providing a secure way to get onto the roof.

- Acoustic Hatches: In buildings where noise is a big concern—think performance venues, recording studios, or facilities near airports—these hatches are built with special sound-dampening materials to stop noise from getting in or out.

Here in Australia, the choice between manual and automated systems usually comes down to practicality and budget. Around 70% of roof hatch installations are manual, prized for being cost-effective and simple to maintain. The other 30% are automatic hatches, a number that’s steadily growing as smart building controls become more common.

This trend is also fuelling a 15% increase in the market for related safety gear like guardrails, heavily influenced by Safe Work Australia regulations. For a deeper dive, check out this report on the roof safety and access system market.

At the end of the day, the type of hatch you choose will come down to its job—is it for daily personnel access, occasional equipment replacement, or fulfilling a specific building code requirement?

Choosing the Right Materials and Finishes

The material your roof hatch is made from is probably the single biggest factor in determining its lifespan, durability, and how well it stands up to the Aussie elements. Think of it like picking the right coat for a harsh winter—the material decides how well it protects what’s underneath. Getting this choice right means your investment will perform reliably for decades to come.

This decision really comes down to a balance between strength, weight, and corrosion resistance. Each material brings its own unique benefits to the table, suited for different environments and security needs, so it’s vital to match the material to your building’s location and purpose.

Comparing Common Hatch Materials

In the world of access hatches for roofs, you’ll typically run into three main contenders: galvanised steel, aluminium, and stainless steel. From a distance, they might look similar, but their properties couldn’t be more different.

- Galvanised Steel: This is your robust, cost-effective workhorse. A protective zinc coating gives it fantastic protection against rust, making it a solid, durable choice for most commercial and industrial sites. It brings superior strength and security to the job.

- Aluminium: Lightweight and naturally resistant to corrosion, aluminium is the go-to choice for coastal areas where salty air can chew through other metals in no time. Its lighter weight also makes installation and day-to-day operation a lot easier, without giving up on durability.

- Stainless Steel: For the absolute best in longevity and resistance to corrosion or chemical exposure, stainless steel is the premium option. You’ll often see it specified for food processing plants, medical facilities, or high-end architectural projects where aesthetics and peak performance are non-negotiable.

If you’re interested in how material choices fit into the bigger picture of construction, you can learn more about the role of sustainable building materials and their impact.

The Importance of Insulation and Finishes

A roof hatch is a break in your building’s thermal seal, which means insulation isn’t just a nice-to-have—it’s essential. An uninsulated hatch can act like a thermal bridge, letting precious heat escape in winter and pour in during summer, sending your energy bills through the roof.

Modern hatches are designed with insulated lids and curbs to stop this from happening. This thermal performance is often measured by a U-value, which tells you how effective a material is as an insulator. The lower the U-value, the better the insulation, which helps prevent heat loss and stops condensation from forming on the inside of the hatch.

A well-insulated roof hatch does more than just provide access; it actively contributes to your building’s energy efficiency, preventing heat transfer and moisture problems that can lead to mould and structural damage.

Finally, let’s talk about the finish. A powder-coated finish is a hugely popular choice for both steel and aluminium hatches. This tough, baked-on paint layer adds another serious barrier against weathering and corrosion. It also lets you match the hatch colour to your roof for a seamless, professional look, adding both aesthetic value and another layer of long-term protection.

Must-Have Features of a Quality Roof Hatch

When you’re looking at roof hatches, it’s easy to get bogged down in materials and basic specs. But what really separates a top-tier hatch from a run-of-the-mill one are the features that make it safe, easy to use, and capable of handling the tough Australian climate. These details are what guarantee long-term reliability.

Think of it this way: a basic box with a lid gets you on the roof, but a quality hatch is an engineered system. Every component is designed to work together for performance and, most importantly, safety.

Effortless Operation and Safety Mechanisms

Trying to wrestle a heavy, awkward lid open on a windy rooftop is a disaster waiting to happen. That’s why gas spring operators are absolutely non-negotiable. They function just like the struts on a car boot, making the opening and closing process smooth, controlled, and almost effortless. It takes the strain off the user and turns a two-person struggle into a safe, one-person job.

Just as critical is a hold-open arm. This simple but vital piece of hardware locks the lid securely in its fully open position. It’s the difference between a hatch that stays put and one that could slam shut in a sudden gust of wind, preventing serious injuries and giving workers peace of mind.

A quality roof hatch should never feel difficult or dangerous to operate. Features like gas springs and hold-open arms transform roof access from a potential hazard into a safe, routine task.

Finally, security is key, which means a heavy-duty locking mechanism is a must. You want a robust slam latch that can be operated from both inside and out. This ensures your team can exit and get back in without the risk of being locked on the roof, all while keeping the building secure from unauthorised entry.

Creating a Watertight Weather Seal

At its core, a roof hatch is a deliberate opening in your roof’s waterproofing membrane, so its ability to keep the weather out is paramount. The single most important element in this fight is the gasket.

A full-perimeter EPDM gasket is the gold standard. EPDM (Ethylene Propylene Diene Monomer) is a tough synthetic rubber that stands up to UV rays, extreme temperatures, and moisture far better than any cheap foam alternative. This continuous gasket creates a compressed, watertight seal when the lid is closed, keeping wind-driven rain and dust where they belong—outside.

Here’s a quick rundown of the features that make a hatch both weatherproof and safe:

- Gas Spring Operators: Delivers smooth, controlled opening and closing, reducing physical effort and boosting user safety.

- Hold-Open Arm: A crucial safety lock that keeps the lid open, stopping it from slamming shut in windy conditions.

- Robust Slam Latch: Secures the hatch firmly and allows for operation from both sides to prevent lock-outs and ensure easy access.

- EPDM Weather Gasket: Forms a durable, long-lasting seal around the entire hatch to block water and air leaks.

When you choose access hatches for roofs with these features, you’re not just getting a safe and easy entry point. You’re also investing in protecting the integrity of your building’s envelope for years to come.

Understanding Installation and Safety Compliance

A top-quality roof hatch is only as good as its installation. Get it wrong, and you’re looking at a whole host of problems, from annoying leaks and structural weak points to genuine safety hazards. That’s why professional installation isn’t just a suggestion—it’s absolutely essential to ensure the hatch works as a seamless part of your building’s safety system.

The job is far more complex than just cutting a hole in the roof and dropping the unit in. A specialist installer first assesses the roof structure to make sure it can handle the new opening and the weight of the hatch. Then, they’ll expertly fit the upstand or curb, which is the raised frame the hatch sits on.

Proper Flashing and Weatherproofing

The single most critical part of any roof hatch installation is the flashing. This is the intricate process of integrating the hatch’s curb with the roof’s waterproofing membrane, creating a flawless, watertight seal that directs water away from the opening.

Without expert flashing, your brand-new access hatch becomes the most likely spot for a leak, which can lead to thousands of dollars in water damage down the track. It’s a precise task that requires a deep understanding of different roofing materials and techniques.

A correctly installed roof hatch is more than an access point; it’s a fully compliant safety system. Adhering to Australian Standards isn’t just about ticking boxes—it’s about ensuring every person who uses it can do so without risk.

Adhering to Australian Safety Standards

Beyond keeping the weather out, meeting safety standards is non-negotiable, especially for commercial properties. In Australia, the key standard is AS 1657, which covers fixed platforms, walkways, stairways, and ladders—the whole system that works with your roof access hatch.

This standard sets out requirements for things like mandatory guardrailing around the hatch opening to prevent falls, making sure a complete, safe system is in place. This focus on safety is a massive driver in the building industry. In fact, the Australian non-residential construction sector accounted for over 55% of all new roof safety installations in 2023.

Proper training is a crucial part of upholding these standards, as outlined in this guide on Health & Safety Training. It’s also worth remembering that major structural changes often need a thumbs-up from the local council. You can get a better idea of what to expect by reading our guide on building permit requirements.

Ultimately, investing in professional installation for your access hatches for roofs is the only way to guarantee safety, compliance, and long-term peace of mind.

Common Questions About Roof Access Hatches

Even once you’ve got a handle on the different types and features, a few practical questions always pop up when you’re choosing and looking after access hatches for roofs. Getting clear, no-nonsense answers to these common queries is the key to making sure you pick the right one and keep it in top shape for years.

We’ve pulled together the questions we hear most often to give you straightforward, practical answers. This should give you the confidence you need to tackle your purchase, installation, and maintenance.

What Is the Standard Size for a Roof Access Hatch?

While you can get hatches made to just about any size, a few common dimensions crop up time and again. For straightforward personnel access, a hatch around 900mm x 700mm is a popular go-to. It gives a maintenance worker enough space to climb through comfortably, even with a small toolbox in hand.

Of course, if you’re planning to move bulky equipment like air conditioning units, you’ll need a much larger double-leaf hatch. The most important thing is to think about how you’ll be using it and what your roof can structurally handle before you lock in a size. It always pays to chat with your manufacturer to make sure the dimensions are spot-on for your project.

How Often Should I Inspect My Hatch?

Regular inspections are non-negotiable for keeping your roof access hatch safe, secure, and weatherproof. A good rule of thumb is to schedule an annual inspection as part of your building’s routine maintenance.

When you’re doing the check, zoom in on a few key components:

- The Seals: Check the EPDM gaskets for any signs of cracking, shrinking, or wear and tear. A busted seal is basically an open invitation for water to get in.

- Gas Struts: Make sure they’re giving you that smooth, controlled lift. If the lid feels like dead weight or slams shut, it’s probably time to replace the struts.

- Locks and Latches: Test that all the locking mechanisms engage properly and are easy to operate from both the inside and out.

- Flashing: Give the flashing around the curb a good look-over for any gaps or damage that might let water sneak through.

If your hatch is in a harsh coastal environment or gets a lot of heavy use, bumping inspections up to twice a year is a smart move.

Proactive maintenance is always cheaper than reactive repairs. A quick 10-minute check can save you from costly water damage down the line and ensure the hatch remains a safe access point.

Can a Roof Hatch Be Installed on Any Roof Type?

Roof hatches are surprisingly versatile and can be installed on most flat or low-slope roofs. This covers your typical commercial roofing structures like concrete, metal deck, and timber. The main difference comes down to the installation method and how the curb is designed to suit that specific roofing material.

It is absolutely vital to bring in a professional for the installation. They have the know-how to ensure the roof opening is structurally sound and, most importantly, that the hatch is perfectly waterproofed. Hatches generally aren’t a good fit for steeply pitched roofs, as that scenario requires specialised engineering and introduces some serious safety risks for anyone trying to use it.

What Are the Most Important Safety Features?

When you’re looking at different roof access hatches, there are a few safety features that should be considered non-negotiable. These elements all work together to protect the user and make sure the whole system is compliant with Australian safety standards.

Here are the must-haves to look for:

- A reliable slam latch that has handles on both the inside and outside, so no one can get accidentally locked out.

- A hold-open arm that securely locks the lid in the open position. This stops it from slamming shut in a gust of wind.

- Gas spring operators to make sure the lid opens and closes in a smooth, controlled way, which helps prevent injuries.

To really nail fall protection, the hatch needs to be integrated with a guardrail system around the opening. This is a requirement for full compliance with safety standards like AS 1657, and it creates a complete, safe access environment for anyone working on the roof.

Ready to bring more natural light and safe access to your property? At Vivid Skylights, we specialise in high-quality roof windows designed for the Australian climate. Explore our range of products and see how we can brighten your space.