When you hear “powder coating,” you might think it’s just another way to paint something. But it’s a whole different ball game. It’s a high-quality, dry finishing process that gives metal surfaces a durable, even, and seriously attractive finish that’s far tougher than conventional paint.

When you hear “powder coating,” you might think it’s just another way to paint something. But it’s a whole different ball game. It’s a high-quality, dry finishing process that gives metal surfaces a durable, even, and seriously attractive finish that’s far tougher than conventional paint.Think of it less like painting and more like baking a protective skin onto an object.

What Is Powder Coating, Exactly?

Imagine trying to get fine dust to stick evenly to a vertical metal surface—it would just slide right off. Powder coating gets around this with a clever bit of science: static electricity. It works just like a balloon sticking to a wall after you’ve rubbed it on your hair.

The process starts by spraying finely ground particles of pigment and resin, which are given an electrostatic charge, onto a grounded metal part. This charge makes the powder particles cling to the surface, wrapping it in a smooth, uniform layer.

Once it’s fully coated, the item heads into a curing oven. The heat melts the powder, causing it to flow and form a seamless liquid film. As it bakes, it chemically hardens, creating a tough finish that’s bonded directly to the metal itself.

The Real Difference From Paint

Unlike your typical liquid paint, which needs solvents to keep everything in a liquid state, powder coating is a completely dry process. This is a massive plus because it means no solvents, and therefore none of the volatile organic compounds (VOCs) that come with them.

The result is a finish that’s not only thicker and more durable than most liquid paints but also much friendlier to the environment. It creates a hard-wearing surface that stands up to chipping, scratching, and fading.

This blend of strength and style is why you see powder coating on so many products we use every day. It provides a superior finish that can handle harsh conditions, making it the perfect choice for anything that needs to look good and last. For instance, all Vivid Skylights frames come powder coated black for that sleek modern look, ensuring they can endure the tough Australian climate while staying sharp for years to come.

Powder Coating vs Traditional Liquid Paint at a Glance

To put it simply, these two methods are worlds apart. Here’s a quick breakdown of how they stack up against each other.

| Feature | Powder Coating | Traditional Liquid Paint |

|---|---|---|

| Application | Dry powder, electrostatically applied and heat-cured. | Wet paint, applied via brushing, rolling, or spraying. |

| Durability | Extremely resistant to chips, scratches, and fading. | Prone to chipping, scratching, and weathering over time. |

| Thickness | Creates a thicker, more uniform finish in one coat. | Often requires multiple coats, can result in drips/runs. |

| Curing Process | Baked in an oven for a hard, cross-linked finish. | Air-dries through solvent evaporation, a slower process. |

| Environmental Impact | No VOCs, minimal waste (overspray can be reused). | Contains VOCs, which are released during drying. |

| Appearance | Smooth, consistent finish with a wide range of textures. | Can be inconsistent; subject to brush marks or orange peel. |

While traditional paint has its place, it’s clear why powder coating has become the go-to for products that demand a flawless and long-lasting finish.

The Three Steps to a Flawless Powder Coated Finish

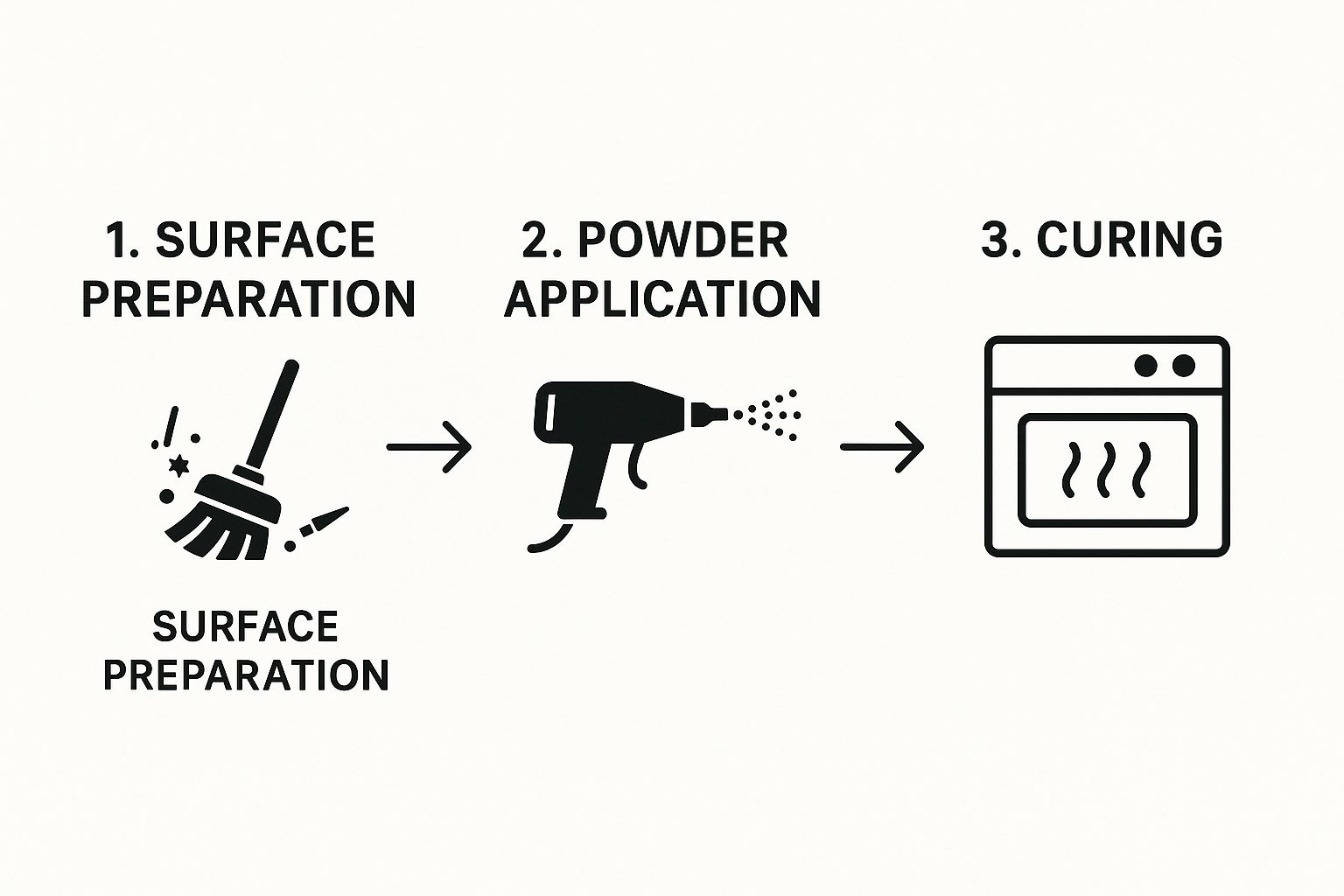

Ever wondered how a fine, dust-like powder turns into a rock-hard, protective skin on a metal surface? It’s not just a simple spray-and-dry job. The process is a careful three-act play combining meticulous preparation, clever physics, and a bit of chemistry to create the famously durable finish you see on high-quality products like our skylight frames.

Step One: Surface Preparation

Before a single grain of powder is sprayed, the metal surface has to be perfectly clean. You could almost say this is the most important stage of all, because the final quality of the coating hinges entirely on how well the powder can grip the metal. Any trace of oil, grease, dirt, or even an old layer of paint will get in the way of a strong, lasting bond.

To get it right, the surface goes through a multi-stage cleaning and pre-treatment process. This usually involves degreasing, rinsing, and applying a special conversion coating. For surfaces that need an even tougher finish, shot blasting is often used. This roughens up the metal just enough to create a textured profile, giving the powder more to cling to and dramatically boosting its durability.

Step Two: Powder Application

With the object perfectly prepped and grounded, it’s time for the real magic. This is where static electricity takes centre stage. The dry powder, which is essentially a mix of finely ground pigment and resin particles, is fed through a special electrostatic spray gun.

As the particles fly out of the nozzle, the gun gives them a positive electrical charge. The metal object, being grounded, has a neutral or negative charge, creating an instant attraction. The positively charged powder particles are drawn to it like a magnet, wrapping around the object and clinging evenly to every single surface, corner, and hard-to-reach crevice. Think of how a balloon sticks to a wall after you rub it on your hair—it’s the same basic principle at work.

This electrostatic pull ensures a remarkably uniform layer of powder, getting rid of the drips and runs you often see with liquid paint. It creates a seamless, even foundation for the final finish.

The popularity of powder coating in Australia is part of a much bigger trend. The Asia Pacific market was valued at USD 3.62 billion in 2024 and is expected to grow by 6.26% each year through to 2033. A huge driver for this growth is its environmental friendliness. Since powder coating emits zero volatile organic compounds (VOCs), it’s a perfect fit for Australia’s push towards cleaner, more sustainable industrial processes. You can read more about the Asia Pacific powder coating market growth and see how sustainability is shaping the industry.

Step Three: Curing

The final step is to lock it all in. The coated object is moved into a large industrial oven for a process called curing. As the heat rises, it melts the powder particles, causing them to flow together and form a smooth, continuous liquid film over the entire surface.

But it’s not just about melting. The heat also kicks off a chemical reaction known as cross-linking, which permanently fuses the resin molecules together. This is the crucial reaction that transforms the melted powder into the hard, resilient, and durable finish that powder coating is famous for. Once it cools down, the coating is fully cured and ready to stand up to chips, scratches, and fading for years to come.

This infographic gives you a simple visual of the three-step powder coating journey.

From the painstaking cleaning to the electrostatic application and the final thermal cure, every stage is vital in creating a superior, long-lasting finish.

Key Benefits of Choosing a Powder Coated Finish

So, why has powder coating become the go-to finish for so many industries, from car manufacturing to high-end architectural products? It really comes down to a powerful mix of practical advantages that traditional liquid paint just can’t keep up with. This isn’t just about looks; it’s about performance, long-term value, and environmental responsibility.

Let’s unpack the four big benefits that make powder coating a superior choice for products that need to last.

Unmatched Durability

First and foremost, powder coating is incredibly tough. The process of heating and curing the powder creates a hard, cross-linked finish that is far more resistant to chipping, scratching, and everyday wear and tear than liquid paint. Think of it as a protective suit of armour for metal.

This toughness makes it perfect for items that get a lot of use or are exposed to the elements—things like outdoor furniture, car wheels, or the sleek frames on our Vivid Skylights. The finish is far less likely to crack, peel, or corrode, which means products keep looking great for much, much longer, even in harsh conditions.

Superior Finish Quality

Have you ever spotted the drips, runs, or faint brush strokes on a painted surface? Powder coating gets rid of those issues entirely. Because the powder is applied using an electrostatic charge, it wraps around the object in a perfectly even layer, getting into every nook and cranny with precision.

The curing process then melts these fine particles into a seamless, uniform skin. The result is a consistently smooth, high-quality finish that’s incredibly difficult to achieve with other methods.

The ability to create a thick, flawless coating in a single application is a key reason why powder coating delivers such a premium and professional appearance.

To get a better sense of the alternatives, you can explore traditional container paint options, which offer a different kind of durable finish. This comparison really highlights the unique, smooth result that only powder coating can provide.

Cost Effectiveness

While it might sound like a more complex process, powder coating is often more cost-effective over the long haul. A huge part of this efficiency is in the application itself. Unlike liquid paint where overspray is just lost, any excess powder can be collected, filtered, and used again.

This transfer efficiency often hits over 95%, which means very little waste and more material ending up right where it belongs—on the product. Cutting down on waste doesn’t just lower material costs; it makes the whole operation more efficient, a saving that can be passed on to the customer.

Environmental Responsibility

In an age where sustainability is more important than ever, powder coating really stands out as a greener choice. The process uses no solvents and releases virtually zero volatile organic compounds (VOCs) into the atmosphere. VOCs are nasty pollutants found in many liquid paints that contribute to air pollution and can cause health problems.

This eco-friendly profile is a major reason for its growing popularity in Australia. The wider paints and coatings industry, with a market size of around USD 2.86 billion in 2024, is increasingly shifting towards powder coating for both its durability and its green credentials. As Australia continues to invest in its AUD 90 billion infrastructure pipeline, the demand for sustainable building solutions is only going to grow, with the market projected to hit USD 4.65 billion by 2034.

Choosing finishes that are kinder to the planet is a crucial part of modern construction. You can learn more by checking out our guide on sustainable building materials. It makes powder coating a smart choice for both performance and the planet.

Exploring the Versatility of Powder Coating Types

Powder coating isn’t a one-size-fits-all solution. Think of it as a whole family of finishes, each with its own personality and purpose. This variety is what makes it so useful, allowing it to be perfectly matched to the job at hand—whether it’s for a heavy-duty industrial part or a sleek architectural feature like a skylight frame.

At its core, the powder used falls into two main chemical families: thermosets and thermoplastics. The key difference between them is how they react to heat during the curing process, which completely changes how they perform.

Thermosets: The Workhorses of the Industry

Thermoset powders are the real backbone of the powder coating world. When they’re heated, something amazing happens—they undergo an irreversible chemical reaction. Their molecules cross-link and fuse together, creating a dense, permanent, and incredibly tough finish.

Once cured, they can’t be melted down and reformed. This gives them exceptional resistance to heat and chemicals, making them perfect for products that need to last.

This category includes some of the most popular and reliable powders out there:

- Polyester: Famous for its fantastic UV resistance and ability to hold colour, polyester is the go-to choice for anything that lives outdoors. It stands up to harsh sun and rain without fading, which is why it’s perfect for window frames, patio furniture, and fencing. All Vivid Skylights frames come powder coated black for that sleek modern look, using a tough polyester powder coat for this very reason.

- Epoxy: If you need serious chemical resistance and hardness, epoxy is your answer. It’s ideal for indoor applications where durability against corrosion is a must, like on industrial equipment, home appliances, and electrical parts.

- Hybrid (Epoxy-Polyester): Just as the name suggests, this is a blend that gives you the best of both worlds. Hybrids offer good chemical resistance and a smooth, attractive finish, making them a common choice for things like office furniture and shelving.

Thermoplastics: The Resilient Protectors

Thermoplastics behave a bit differently. When heated, they melt and flow to form a smooth coating, but they don’t go through that permanent chemical change. This means they can technically be remelted and reshaped if needed.

These coatings are usually applied thicker, creating a finish that feels softer and is more resistant to impacts. While you won’t see them as often in architectural uses, they’re brilliant for creating a tough, almost rubber-like protective layer on things like tool handles and playground equipment.

Beyond the chemistry, the real fun begins with the aesthetics. Powder coating offers an almost endless palette of visual effects, letting designers and architects achieve the exact look and feel they’re after. The right finish can turn a simple metal object into a premium product.

Exploring the various options available, like those used in our durable double glazed skylights, shows just how a great finish can complement both form and function.

The real creative freedom in powder coating comes from its finishes. From a high-gloss, liquid-like sheen to a sophisticated matte black, the visual possibilities are immense, allowing for complete customisation.

The visual options don’t stop at colour. You can also get:

- Textured Finishes: These create a tactile surface that not only looks rugged and durable but is also great for hiding minor surface imperfections.

- Metallic Effects: Powders can be mixed with metallic flakes to produce everything from a subtle shimmer to a bold, sparkling finish that really catches the eye.

- Wrinkle Finishes: This unique effect creates a distinctive, textured pattern that is both visually interesting and fantastic at concealing fingerprints and everyday wear.

To make it easier to see which powder type works best where, we’ve put together a simple table.

Common Powder Coating Types and Their Best Uses

This table breaks down the most common types of powder coatings, outlining their key characteristics and typical applications.

| Powder Type | Key Strengths | Ideal Applications |

|---|---|---|

| Polyester | Excellent UV and weather resistance, great colour retention | Outdoor furniture, window/door frames, fencing, architectural fittings |

| Epoxy | Superior chemical and corrosion resistance, very hard and durable | Indoor industrial equipment, appliances, electrical components, automotive parts |

| Epoxy-Polyester Hybrid | Good all-around performance, smooth finish, cost-effective | Office furniture, shelving, indoor lighting fixtures, general indoor metal goods |

| Thermoplastics (e.g., PVC, Nylon) | Extremely impact-resistant, soft feel, thick protective layer | Tool handles, playground equipment, wire baskets, outdoor seating |

As you can see, the choice of powder really depends on where and how the final product will be used. By picking the right chemistry and finish, you can ensure a product that not only looks fantastic but also stands up to whatever life throws at it.

Where You Will Find Powder Coating in Everyday Life

Once you know what to look for, you’ll start seeing powder coating everywhere. It’s not just for massive industrial gear; this incredibly durable finish is on countless items you use every day, protecting them from the daily grind while keeping them looking great. It’s this unique mix of toughness and style that has made it a go-to choice across so many different industries.

You’ll spot it on car parts like wheels and roof racks, where it has to stand up to flying road debris and whatever the weather throws at it. It’s also all over your home appliances, from the body of your washing machine to the front of your fridge, giving them a finish that resists scratches and wipes clean easily. Even things like park benches, bicycle frames, and playground equipment rely on powder coating for their bright, long-lasting colours.

For a simple example of how it makes everyday items better, just look at something like a matte red powder-coated stainless steel flask. It’s a perfect showcase of how a functional item becomes both tougher and way more visually appealing with a quality powder coat.

Its Critical Role in Architecture

One of the biggest and most important uses for powder coating is in architecture. In this field, building materials have to do two things perfectly: look fantastic and stand up to the elements for decades. This is exactly why powder-coated aluminium has become the benchmark for window frames, balustrades, fencing, and facade panels.

Architectural aluminium needs a finish that can handle relentless sun, driving rain, and constant temperature changes without fading, chipping, or corroding. A high-quality polyester powder coat acts as a protective shield against all of it.

This is precisely why all Vivid Skylights frames come powder coated black for that sleek modern look. The finish isn’t just about looks; it’s a vital layer of defence against the harsh Australian climate, making sure our products hold their own and keep their appearance for years with minimal upkeep.

The smooth, uniform finish gives a sophisticated look that fits perfectly with modern design, while its built-in durability guarantees it will last. You can see how this finish is a core part of the product’s performance by checking out our skylight frame construction.

Powering Australian Industry

Beyond our homes and buildings, powder coating is a fundamental technology in Australia’s major industrial sectors. In fields like manufacturing, construction, and resource extraction, toughness and corrosion resistance aren’t just nice to have—they’re essential.

Take Australia’s oil and gas industry, which produced over 461,000 barrels of petroleum liquids per day in 2021. It depends on advanced coatings to protect its equipment in some of the most punishing conditions imaginable. Components have to survive extreme temperatures, high pressure, and chemical exposure, and powder coatings provide that tough, reliable barrier that stops corrosion and prevents equipment failure.

From the car you drive to the buildings you live and work in, this robust finish is one of the unsung heroes of modern life.

Still Have Questions About Powder Coating?

Even after getting the gist of what powder coating is, a few practical questions always seem to pop up. It’s completely normal.

Here, we’ll tackle the most common queries we hear. The goal is to clear up any lingering doubts so you can feel confident choosing this superior finish for your projects, whether it’s for architectural elements or automotive parts.

How Long Does Powder Coating Last?

This is one of the biggest draws of powder coating—its incredible lifespan. A professionally applied finish can easily last for 15 to 20 years, and sometimes even longer, depending on where it’s used and the type of powder. The secret to its longevity is its stubborn resistance to chipping, scratching, and fading.

Unlike traditional liquid paint, which can start to look tired and worn after a few years of UV light and moisture, a powder-coated surface holds its colour and integrity for a very long time. This makes it a genuinely smart long-term investment for anything that has to stand up to the elements, like the aluminium frames on our skylights.

Can You Powder Coat Any Material?

While it’s an incredibly versatile finish, powder coating doesn’t work on everything. The whole process hinges on two key requirements: the material must be able to hold an electrostatic charge, and it needs to handle the heat of a curing oven, which typically runs between 160°C to 210°C.

This makes it a perfect match for most metals, including:

- Aluminium: It’s lightweight, naturally resists corrosion, and takes to powder coating beautifully.

- Steel: Both mild and stainless steel are routinely powder coated to give them that extra layer of toughness.

- Brass and Copper: These metals also work well with the process, resulting in a durable, high-quality finish.

On the other hand, materials that can’t take the heat—like wood, plastic, and rubber—are generally not suitable for standard powder coating methods.

At its core, powder coating is made for conductive materials that can survive a trip through a hot oven. It’s exactly why it has become the gold standard for finishing metal products that need to be both tough and long-lasting.

How Heat Resistant Is a Powder-Coated Finish?

The heat resistance really comes down to the type of resin used in the powder itself. Your standard polyester powders, which are fantastic for outdoor architectural use, can typically handle continuous temperatures up to around 100°C to 150°C without breaking a sweat.

But for more extreme situations, like coating engine parts or exhaust systems, there are specialised silicone-based or ceramic powders. These high-temperature coatings are built to withstand heat well over 500°C, creating a protective shield in even the most demanding environments. It’s this kind of flexibility that ensures there’s a powder coating solution for almost any level of heat.

For a finish that combines sleek, modern aesthetics with unbeatable durability against the harsh Australian climate, you can’t go wrong. Vivid Skylights uses a premium black powder coat on all our aluminium frames, ensuring your investment not only looks incredible but is built to last for years. Discover the difference a quality finish makes and bring more light into your home by exploring our range at https://vividskylights.com.au.